Applications: MAST Platform

The bioprocessing industry requires a reliable system for transferring samples directly from bioreactors to analytical devices while maintaining process sterility. That’s why we developed the MAST platform.

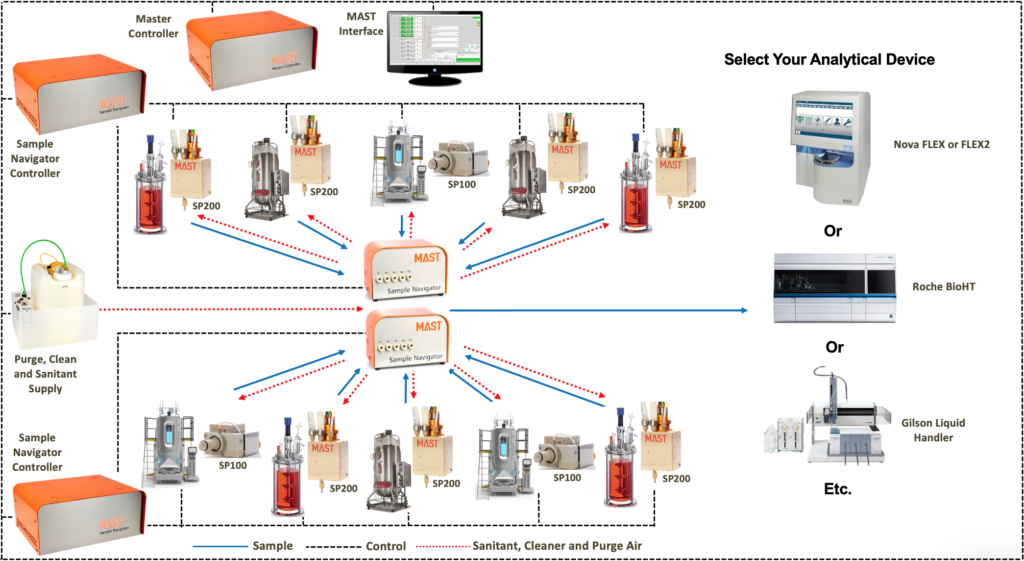

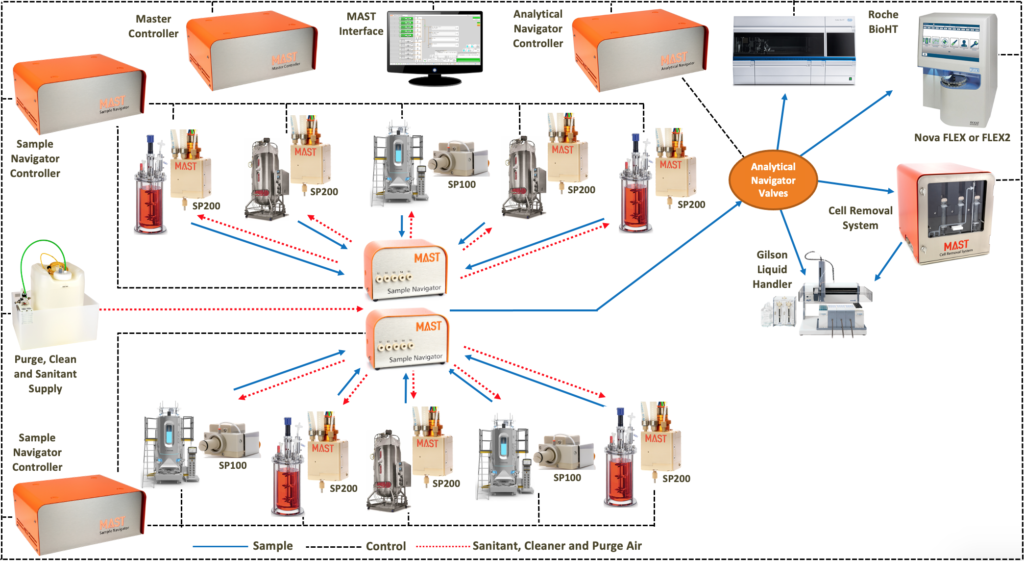

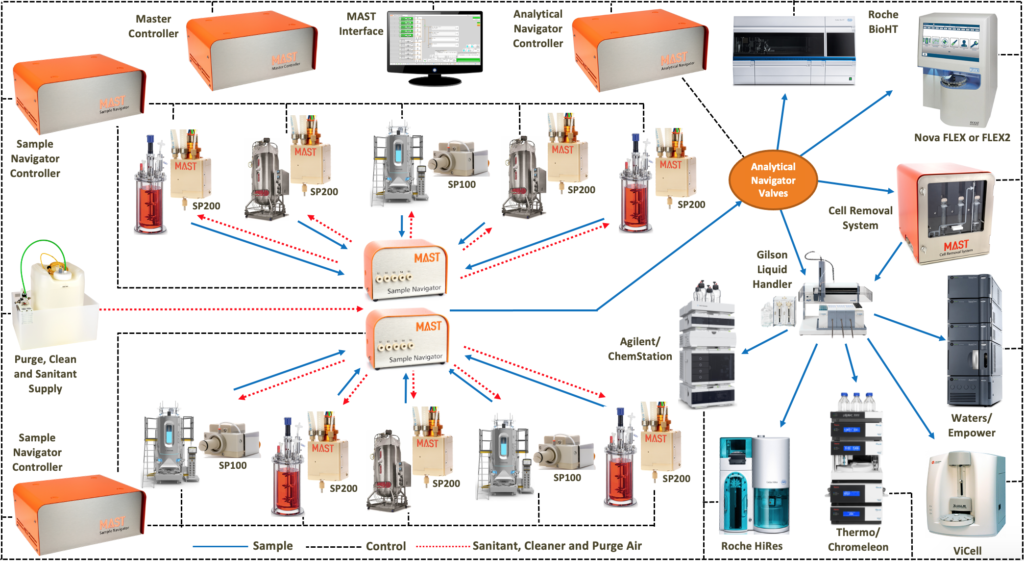

This automated, aseptic bioreactor sampling system for development and commercial scale applications enables optimized sampling of media, cell and product-level information across scales. The MAST platform has multiple modules and can be easily adapted to your specific requirements and existing technology.

Benefits include:

- The ability to collect process and product attribute data in near real time, enabling product quality attribute control

- Confidence that your sample is a true representation of the entire broth

- Seamlessly scalable from development through full-scale cGMP manufacturing

- Fully modular design grows and changes to your needs

- Aseptic zone to draw the sample into, increasing your sterility assurance profile

- Closed system, high-pressure cleaning, sanitization, and drying process after each sample

- Positive displacement pump on board the Sample Pilot, facilitating delivery of the most viscous sample-extended distances

- Cell Removal System that is external to the bioreactor

- Fast bioreactor set-up time

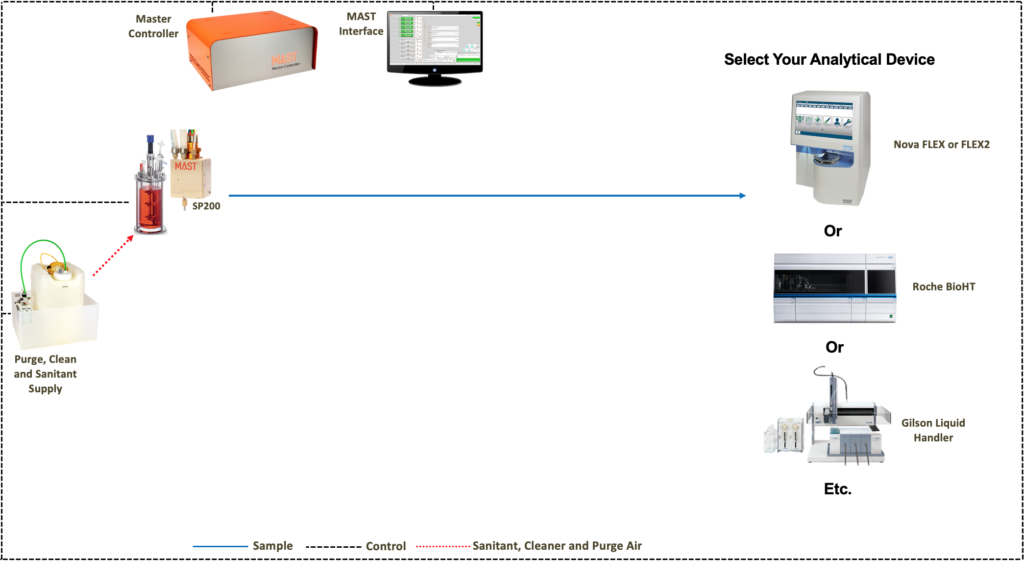

With its modular design, the MAST platform can be installed to meet your most basic needs and can be readily expanded as your application evolves. For example, the most basic system, what we call the MAST Core, can collect samples from one bioreactor or other source and deliver that sample to one destination such as a Nova BioProfile FLEX, MAST Cell Removal System or a Gilson Liquid Handler.

The most basic system, what we call the MAST Core, can collect samples from one bioreactor or other source and deliver that sample to one destination such as a Nova BioProfile FLEX, MAST Cell Removal System or a Gilson Liquid Handler.